specification

Main Technical Parameters | GMC3025 | GMC4025 | GMC5025 | GMC6025 | |

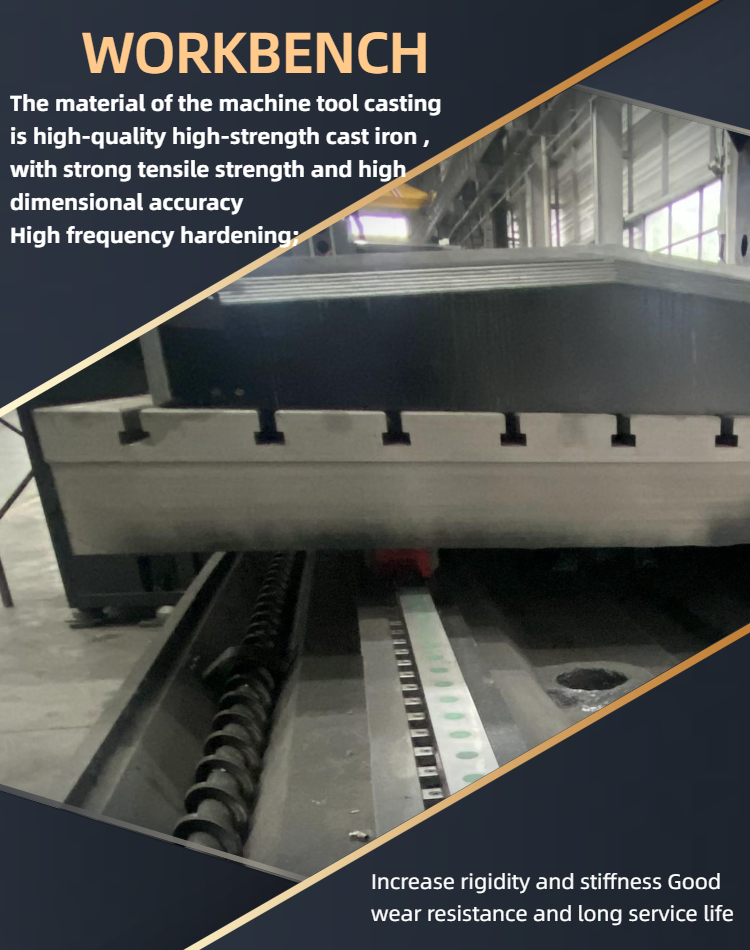

Work table size (width × length) (mm) | 2300×3000 | 2300×4000 | 2300×5000 | 2300×6000 | |

Stroke in the moving direction of the table (X-axis mm) | 3000 | 4000 | 5000 | 6000 | |

Stroke in the moving direction of the spindle carriage (Y-axis mm) | 2700(side stroke 3050) | 2700(side stroke 3050) | 2700(side stroke 3050) | 2700(side stroke 3050) | |

Stroke in the up and down movement direction of the spindle (Z axis mm) | 1000 | 1000 | 1000 | 1000 | |

Gantry width (mm) | 2700 | 2700 | 2700 | 2700 | |

Gantry is too high (mm) | 1400 | 1400 | 1400 | 1400 | |

Distance from spindle end face to work table (mm) | 280-1280(Optional heightening 250,300,400) | 280-1280(Optional heightening 250,300,400) | 280-1280(Optional heightening 250,300,400) | 280-1280(Optional heightening 250,300,400) | |

Table T-slot (number - size x spacing) | 11-28×200 | 11-28×200 | 11-28×200 | 11-28×200 | |

Spindle Specifications (Model/Installation Diameter) | BT50/Φ200 | BT50/Φ200 | BT50/Φ200 | BT50/Φ200 | |

Spindle transmission mode | belt | Speed 6000r/min | Speed 6000r/min | Speed 6000r/min | Speed 6000r/min |

the transmission ratio is 1.5:1;(optional 1.5:1) | the transmission ratio is 1.5:1;(optional 1.5:1) | the transmission ratio is 1.5:1;(optional 1.5:1) | the transmission ratio is 1.5:1;(optional 1.5:1) | ||

ZF deceleration + belt (optional) | The speed is 6000r/min and the transmission ratio is 4:1; | The speed is 6000r/min and the transmission ratio is 4:1; | The speed is 6000r/min and the transmission ratio is 4:1; | The speed is 6000r/min and the transmission ratio is 4:1; | |

Gear Head (Weimars) | speed 6000r/min, Transmission ratio 4.4:1 | speed 6000r/min, Transmission ratio 4.4:1 | speed 6000r/min, Transmission ratio 4.4:1 | speed 6000r/min, Transmission ratio 4.4:1 | |

Rapid traverse feed rate (m/min) | 10 | 10 | 10 | 10 | |

Cutting feed rate (m/min) | 6 | 6 | 6 | 6 | |

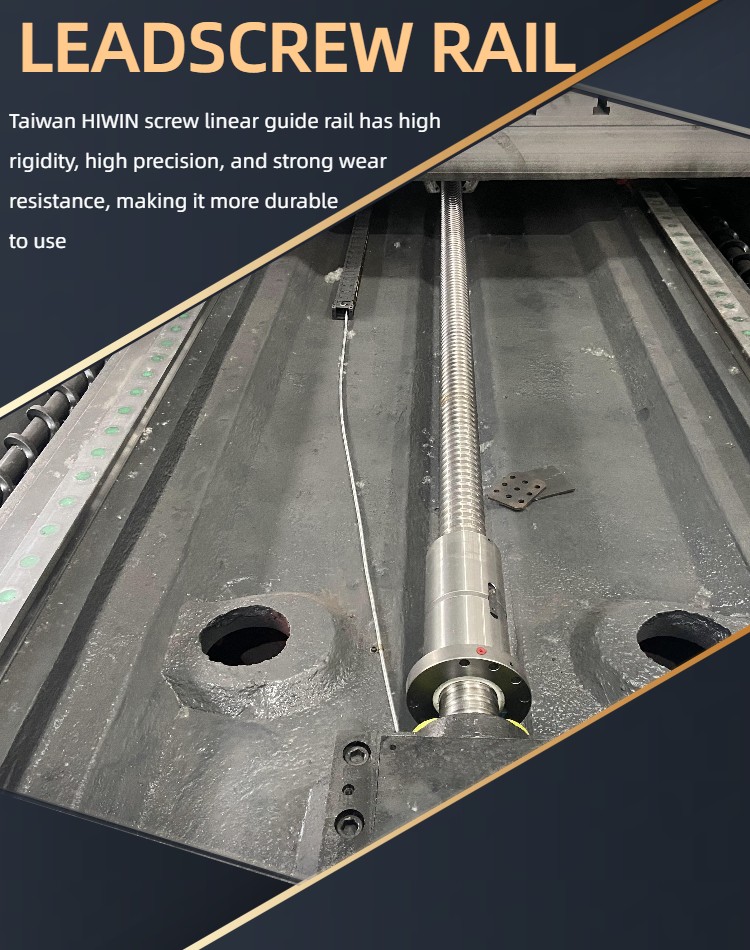

X, Y, Z axis ball screw specifications/pitch | X:8020, Y:6316, Z:5010 | X:8020, Y:6316, Z:5010 | X:8020, Y:6316, Z:5010 | X:8020, Y:6316, Z:5010 | |

X, Y, Z axis guide rail specifications / number of sliders | X axis: roller guide 55/10; | X axis: roller guide 55/14; | X axis: roller guide 55/14; | X axis: roller guide 55/14; | |

Y axis: roller guide 55/4; | Y axis: roller guide 55/4; | Y axis: roller guide 55/4; | Y axis: roller guide 55/4; | ||

Z axis: rectangular slide | Z axis: rectangular slide | Z axis: rectangular slide | Z axis: rectangular slide | ||

X, Y, Z axis servo motor transmission mode and transmission ratio | X-axis planetary gear transmission 4:1 X-axis planetary gear transmission 3:1 Z-axis direct drive 1:1 (Optional X-axis belt drive 2.5:1; Y-axis direct drive 1:1; X-axis direct drive 1:1) | X-axis planetary gear transmission 4:1 X-axis planetary gear transmission 3:1 Z-axis direct drive 1:1 (Optional X-axis belt drive 2.5:1; Y-axis direct drive 1:1; X-axis direct drive 1:1) | X-axis planetary gear transmission 4:1 X-axis planetary gear transmission 3:1 Z-axis direct drive 1:1 (Optional X-axis belt drive 2.5:1; Y-axis direct drive 1:1; X-axis direct drive 1:1) | X-axis planetary gear transmission 4:1 X-axis planetary gear transmission 3:1 Z-axis direct drive 1:1 (Optional X-axis belt drive 2.5:1; Y-axis direct drive 1:1; X-axis direct drive 1:1) | |

Spindle motor selection recommendation | 22kW wide area motor | 22kW wide area motor | 22kW wide area motor | 22kW wide area motor | |

X, Y, Z three-phase servo motor recommendation | ≥ X:50N m; Y:40N m; Z:30N m (brake) | ≥ X:50N m; Y:40N m; Z:30N m (brake) | ≥ X:50N m; Y:40N m; Z:30N m (brake) | ≥ X:50N m; Y:40N m; Z:30N m (brake) | |

Optical machine dimensions | 7750×5140×4100 | 9750×5140×4100 | 11750×5140×4100 | 13750×5140×4100 | |

(length × width × height) (mm) | |||||

Workbench load (t) | 10 | 12 | 15 | 18 | |

Light machine weight about (t) | 33 | 38 | 43 | 50 | |

Details Display

Company Profile